ProaXesS

Powered by VEKTOR DIREKTOR

Process Monitoring and Control Platform for All Industries Utilising Inline Sensors and PAT

- Highly Configurable and Connects to Many Data Sources.

- Utilises Process Models Developed in VEKTOR DIREKTOR.

- Multivariate and Univariate Statistical Process Control.

- Expert and Non-expert Data Visualisation and Dashboards.

- OPC Connectivity for Integration with Third-party Process Control Systems.

- In-built Database Schema.

Drag it, drop it, use it. It’s that simple.

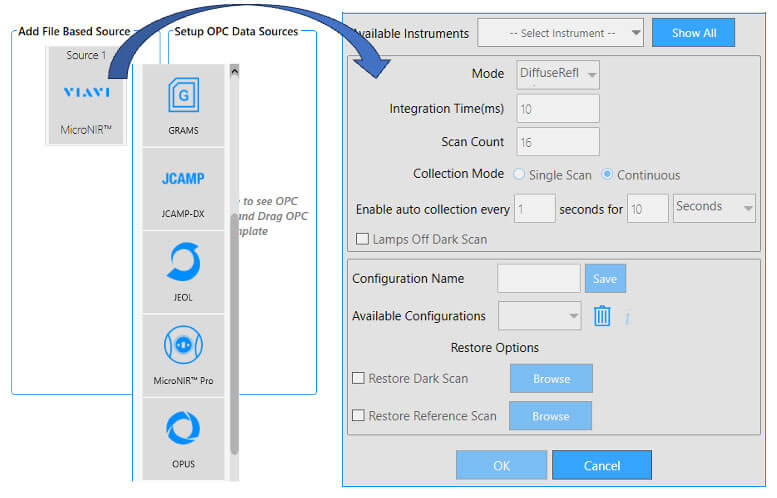

Data Input and Drivers

Easy Drag’n’Drop Setup

- File Based Formats.

- Instrument Drivers.

- OPC Templates.

Can Setup Single or Multiple Imports into a Single Configuration.

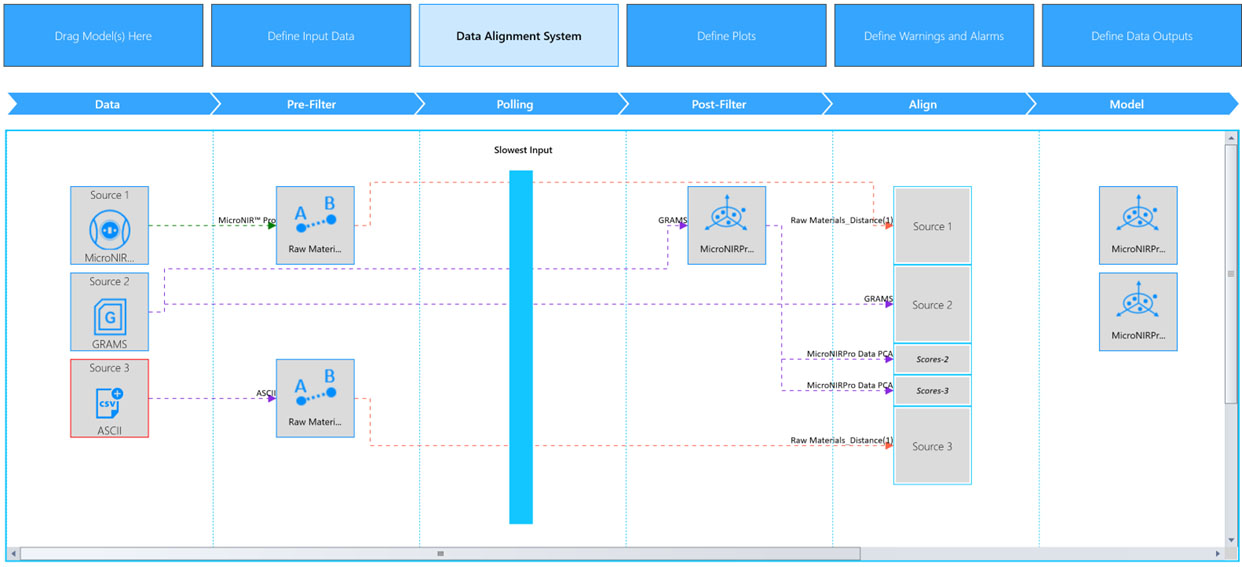

Data Alignment

The Data Alignment System (DAS-Box) is the Most Intuitive Method for Aligning Individual Data Sources to a Common Time Point

DAS-Box is a workflow system that allows you to,

- Apply Spectral Filters to Remove Non-Sample Data.

- Align Data Using a Number of Methods.

- Apply Post Filters to Extract Important Information From Data.

- Defining the Order of Aligned Data.

- Application of VEKTOR DIREKTOR Models to All or Selected Parts of the Aligned Array.

“What good is a process if you can’t control it?”

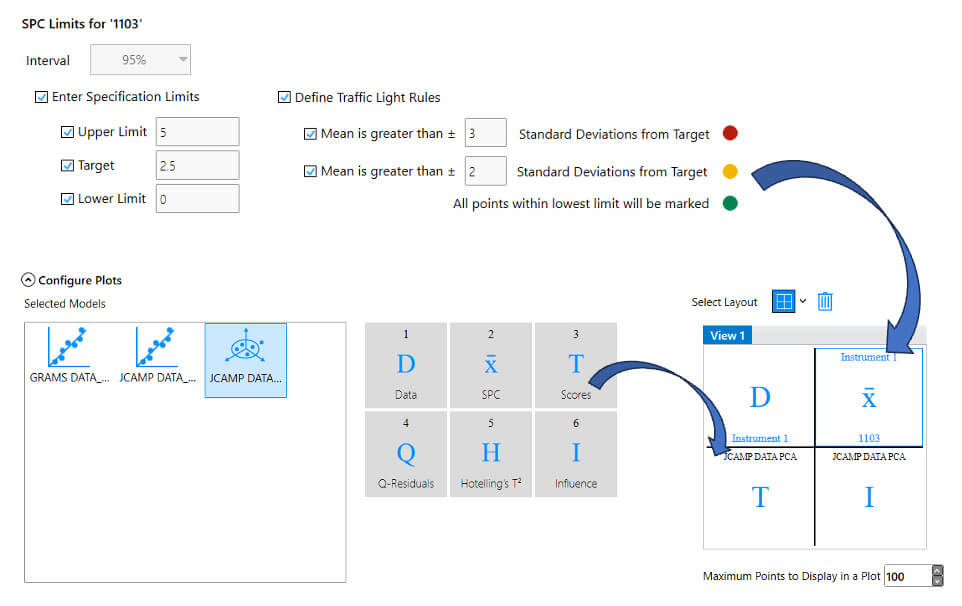

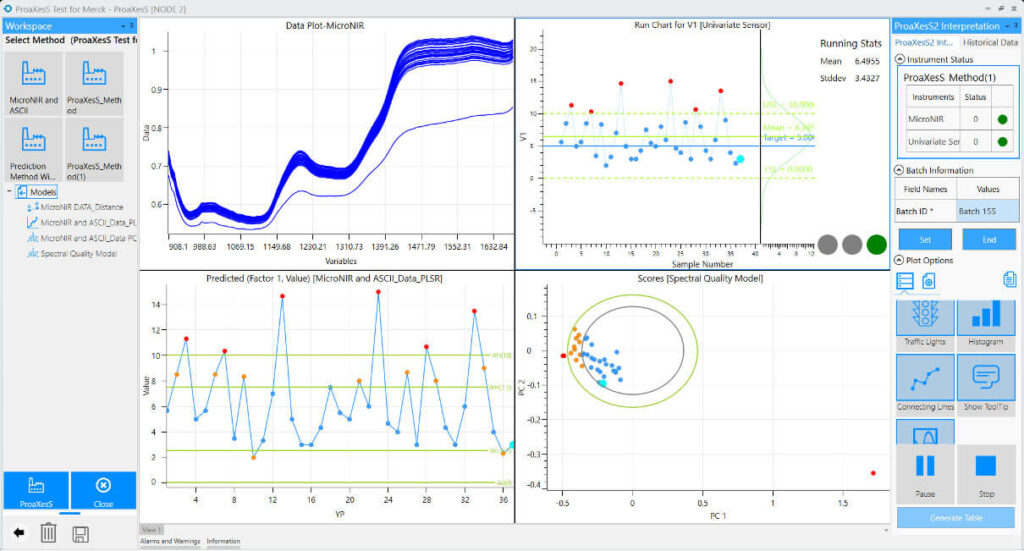

Visualisation of Results

Configurable Plot Layouts and Dashboards

- Set up Statistical Process Control (SPC) Charts.

- Display Raw and Preprocessed Data.

- Display Results of Multiple VEKTOR DIREKTOR MVDA Models.

- Define the Views for the End User with the Interactive Plot Layout Tool.

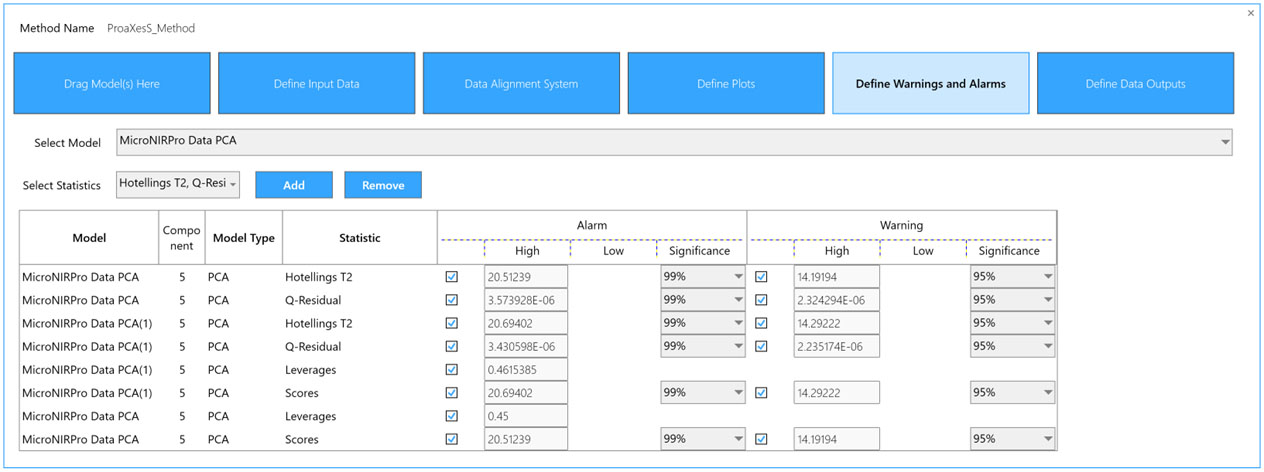

Multivariate Model Alarms and Warnings

Define Limits for Selected Statistics in Each Model

- Select Any Model Used in the Configuration.

- Select Only the Statistics to Evaluate with Alarms on Warnings.

- Define the Limits and Confidence Intervals for the Selected Statistics.

“Simplicity in configuration setup using an intuitive workflow

translates to faster implementation and validation.”

A Happy Process Engineer

Real Time Information

Visually Assess Process Trends and Verify the Identity of Outliers

- Display Statistics with Limits in Real Time.

- List Alarm and Warnings and Use the Outputs for Process Control.

- Interact with Plots in Real Time to Drill Down into Important Events.

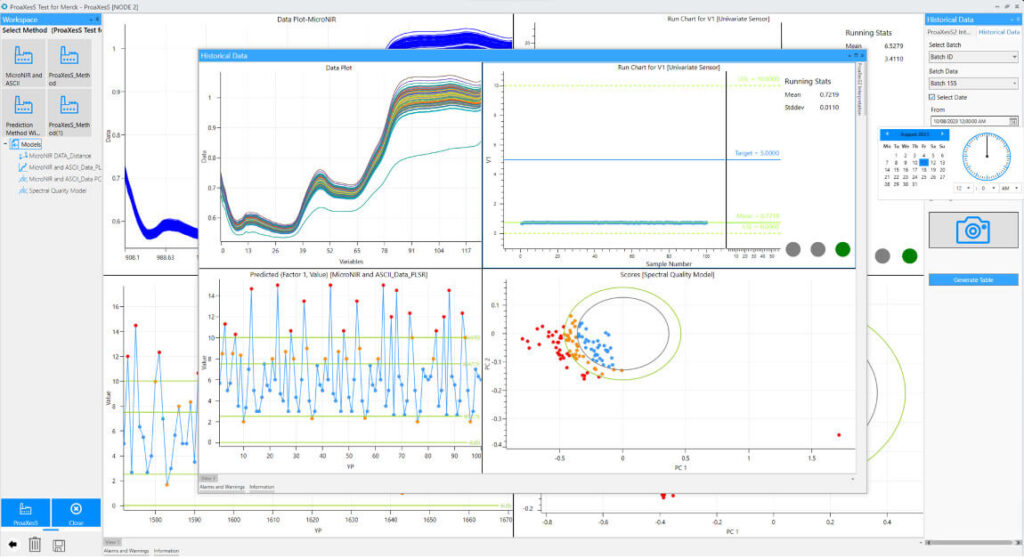

Historical Data Retrieval

Search the database for past results and interactive views

- Retrieve Historical Data Using ProaXesS Query Tools.

- Combine Batch Data Results for Comparison.

- Export Data Directly to VEKTOR DIREKTOR for Model Building and Root Cause Analysis.

System Requirements and Features

| Supported Operating Systems | Windows 10 or later (64-bit) |

| Memory (RAM) | 8 GB Minimum. |

| Processor Specification | 2 GHz or faster, quad-core, x64-based |

| Hard Disk Space | 8 GB of available disk space |

| .NET Framework | 4.8 |

| Security | Windows Authentication, VEKTOR VAULT (optional)

Windows Authentication with Administrator, Developer and Operator levels of access |

| Data Imports | ASCII (.csv), Proprietary Instrument Formats, OPC UA and DA, Direct Instrument Drivers, Database |

| Security | Windows Authentication with Administrator, Developer and Operator levels of access |

| Data Alignment (Optional) | User defined |

| Database | VEKTOR DATABASE Proprietary Database Schema |

| Models | Principal Component Analysis (PCA) Projection, Partial Least Squares Regression (PLS) Prediction, Multiple Linear Regression (MLR) Prediction, Distance Models (Outlier Rejection) |

| Statistical Process Control (SPC) | Line, scatter and control charts with limits and outlier detection |

| Alarms and Warnings | Available for all models and sent as OPC tags |

| Dashboards | Customised Dashboards Based on End User Requirements |